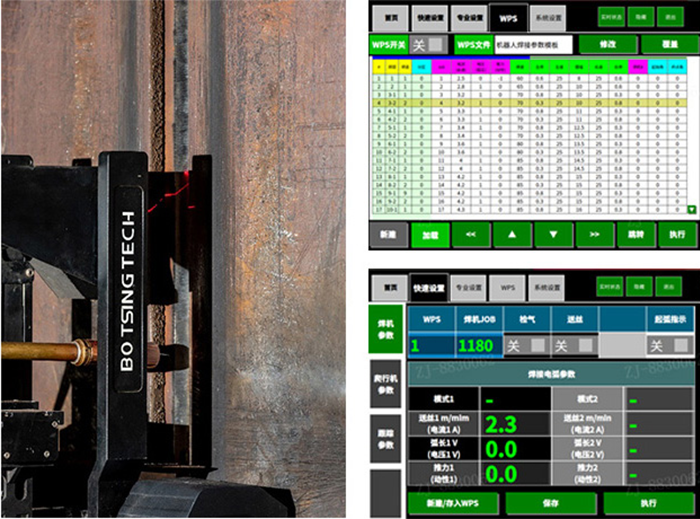

Adaptive Welding Process Technology

① Realize adaptive control of welding parameters for welding power sources by robots through digital communication interfaces.

② Embedded WPS system, which can store welding parameters and quickly call and switch.

③ By adaptive control of welding process parameters and welding positions, full position automatic continuous welding is achieved, improving the efficiency of full position welding of large structural components.

④ By using laser sensors to identify characteristic information such as the width, angle, and depth of the welding groove, adaptive control of the welding gun action is achieved.

② Embedded WPS system, which can store welding parameters and quickly call and switch.

③ By adaptive control of welding process parameters and welding positions, full position automatic continuous welding is achieved, improving the efficiency of full position welding of large structural components.

④ By using laser sensors to identify characteristic information such as the width, angle, and depth of the welding groove, adaptive control of the welding gun action is achieved.

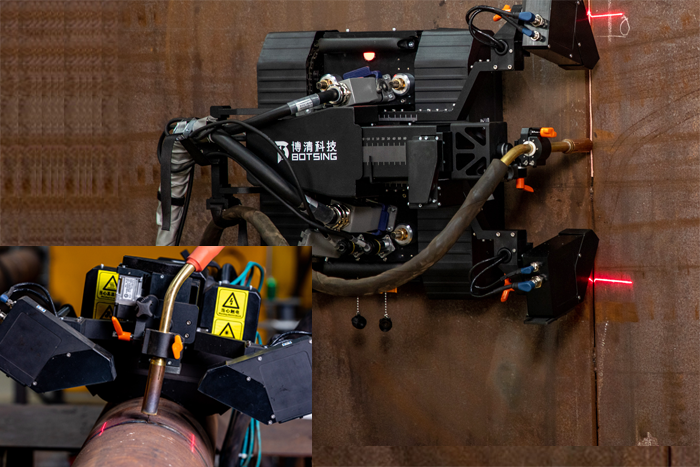

Seam Tracking Technology

① Equipped with laser sensors, attitude sensors and other sensor equipment to realize the independent identification and tracking of welds.

② Equipped with dual laser sensors, by switching the direction of the laser sensor, the two-way welding of the welding bead and the automatic retraction of the robot are realized.

③ The laser sensor weld tracking algorithm, through the development of dearc light splash algorithm and weld image detection algorithm, realizes the improvement of grasping accuracy, arc light resistance and anti-splashing ability, and improves the adaptability to the change of laser line light and darkness and groove width.

② Equipped with dual laser sensors, by switching the direction of the laser sensor, the two-way welding of the welding bead and the automatic retraction of the robot are realized.

③ The laser sensor weld tracking algorithm, through the development of dearc light splash algorithm and weld image detection algorithm, realizes the improvement of grasping accuracy, arc light resistance and anti-splashing ability, and improves the adaptability to the change of laser line light and darkness and groove width.

Molten Pool Observation

The product can be equipped with a molten pool observation camera for remote monitoring of open arc welding, which can be used to judge the degree of fusion and realize remote real-time control and adjustment of the welding process.。

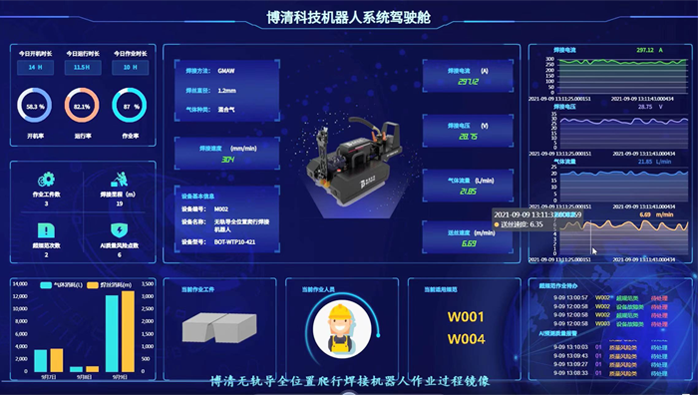

Intelligent Welding System

It adopts advanced intelligent welding management system, including welding resource platform, welding site intelligent control collection system and welding data statistical analysis system, integrates enterprise welding-related resources, and carries out systematic and standardized management through software to achieve efficient utilization of resources, cost reduction and efficiency.

① Welding process visualization

② AI intelligent real-time diagnosis

③ Process parameter big data collection and processing

① Welding process visualization

② AI intelligent real-time diagnosis

③ Process parameter big data collection and processing